Unlocking East Africa’s Potential

Known for many years as an area where natural oil seepages occurred, oil was first discovered by drilling in the Lake Albert area of Uganda in 2006. This first discovery led to an extensive period of further exploration and appraisal which was completed in 2014.

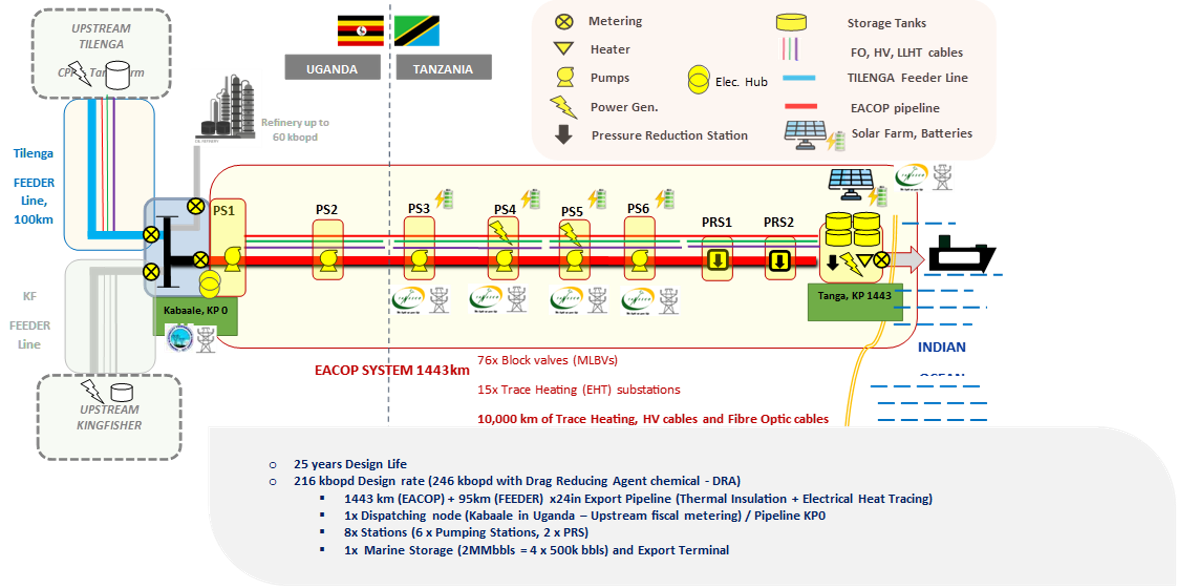

EACOP is being constructed in parallel with two upstream development projects which are not part of EACOP development and investment, known as Tilenga and Kingfisher, respectively. Each development will consist of a Central Processing Facility (CPF) to separate and treat the oil, water and gas produced by the wells. Kingfisher will have 4 well pads and a CPF with a peak daily capacity of 42,000 bbl/d. Tilenga has 31 wellpads and a 204,000 bbl/d CPF.

Tilenga and Kingfisher CPFs will be connected by feeder lines to the starting point of EACOP at Kabaale. Here the oil will be metered and then comingled into a single stream. The Ugandan Refinery project has a right of first call to 60,000 bbl/d, with the remainder of the oil being exported via EACOP.

The pipeline route via Tanzania was confirmed in April 2016 at a summit with the East African Heads of State. In the period 2016-2018, the EACOP route was studied and narrowed down to its final width of 30 metres, allowing to then initiate land surveys and the Environmental and Social Impact Assessments.

This EACOP will be designed, constructed, financed and operated through a dedicated Pipeline Company with the same name. The shareholders in EACOP are affiliates of the three Upstream joint venture partners (the Uganda National Oil Company, TotalEnergies EP Uganda and CNOOC Uganda) together with the Tanzania Petroleum Development Corporation. Shareholdings are TotalEnergies 62%, UNOC and TPDC 15% each and CNOOC 8%.

EACOP has established a commercial and legal framework including:

EACOP is a 1,443km crude oil export pipeline that will transport Uganda’s crude oil from Kabaale – Hoima in Uganda to the Chongoleani Peninsula near Tanga port in Tanzania. It will have a peak capacity of 246,000 bbls/day.

Electrical power is required for the pipeline’s operation, both for the Pumping Stations, the Terminal operations and maintaining the crude oil temperature. In Uganda power will be taken firstly from any surplus power generated at Tilenga and Kingfisher, and then from the National Grid, the electricity being generated in Uganda’s hydro-power stations. In Tanzania EACOP will have its own power generation, with generators available as back-up to support an electrical power scheme primarily based on connection to Tanzanian grid at all 4 pump stations in Tanzania and at the terminal. Electrical production at the terminal will be also complemented by a solar farm (4MWp in total capacity).

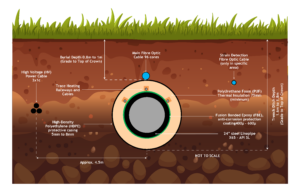

A number of measures are taken during the design, construction and operational phases to ensure that the pipeline operates correctly during its 25 year lifetime. These include:

© 2025 East African Crude Pipeline – All Rights Reserved

Course View Towers,

Plot 21, Yusuf Lule Road

P. O. Box 135596,

Kampala, Uganda

Tel: +256 (0) 204 916 000,

Toll Free: 0800 216 000

Email: [email protected]

18th Floor, 10 Upper Bank Street, London, United Kingdom E14 5BF

Msasani Penninsula,

Plot no. 1403

Bains Avenue off Chole Road.

P. O. Box 23139,

Dar es Salaam, Tanzania

Email: [email protected]